Choose a different country or region to see the content specific to your location

Select Your Country/Region

Current Region:

Global (EN)

Global (EN)

How can we help you?

The use of nitrogen in the food and beverage industries is increasing in popularity due to its inherent capability to preserve both raw materials and the final product. By taking advantage of the physical properties of nitrogen, food and beverage companies drive important improvements affecting both the productivity of their operations as well as consumer reception of their product.

Nitrogen is used to eliminate oxygen, thereby minimizing flavor changing effects and waste that oxidation has on both raw materials and finished product. When storing raw materials such as vegetable oils, fragrances and flavors, a nitrogen atmosphere helps stabilize the product and preserve taste. Additionally, many products such as grains and aerosols will present an explosion hazard which is eliminated in an oxygen free environment.

With the expanding use of nitrogen, traditional sourcing via bulk supply delivery is often yielding to the more cost effective and operationally flexible solution provided by an on-site nitrogen generator. With a nitrogen generator, productivity improvements range from reduced supply costs to the operational benefits of flexibility in tailoring the nitrogen purity and consumption patterns to meet production needs.

Holtec is the leading manufacturer of high-quality, high-efficiency nitrogen generators for the food & beverage industries. We have engineered systems for beer, nuts, grains, sausage, cheese, coffee, juice, milk, soft drink, vegetable oil, seed, popcorn, cheese, and many other applications.

From our deep industrial experience to our commitment to continuous product improvement, we are the benchmark for performance and reliability of Nitrogen Generators.

Our strength is the ability to supply systems scaled to your needs; whether those are pilot plants, complete multi-line operations or warehousing implementations. Food and beverage applications often come with unique requirements such as stainless steel for all food-serving piping, raised legs and waterproof enclosures for easier wash downs, or integrating remote O2 analyzers to check quality right at the product packaging. Going beyond the obvious, you can draw upon our experiences to help you prepare for tomorrow as strategies for flexibility, including capacity expansion, are a must in the dynamic environment of managing food and beverage process lines.

Pilot Plant Scalability – Designs optimized for small scale capacities enable technicians, process engineers and operations managers to evaluate the use of nitrogen in a low-risk environment prior to scale-up.

Return on Investment vs. Bulk N2 – Rising global nitrogen usage has resulted in sharp price increases for bulk liquid nitrogen and compressed gas cylinders. Producing your own nitrogen is less costly; limited to consumed electricity and annual maintenance. ROI is typically less than one year not including the inherent benefits associated with shelf life improvements for both the raw materials and the finished bottled product.

Plant safety – Self-generated nitrogen is typically created and stored at about 100 psi (6.9 bar), whereas high pressure cylinders are typically filled to 2000 psi (138 bar) or more. Super-cooled liquid nitrogen allows for the storage of nearly 700 times more mass than in a similar volume of gas. Both of these situations represent a tremendous amount of stored energy which demands rigorous safety protocols. Conversely, self-generated nitrogen demands only the same safety procedures required for compressed air, which most plants are already using.

Flexibility – Nitrogen generators free your facility from mandatory contract terms, including price increases, imposed by liquid nitrogen suppliers.

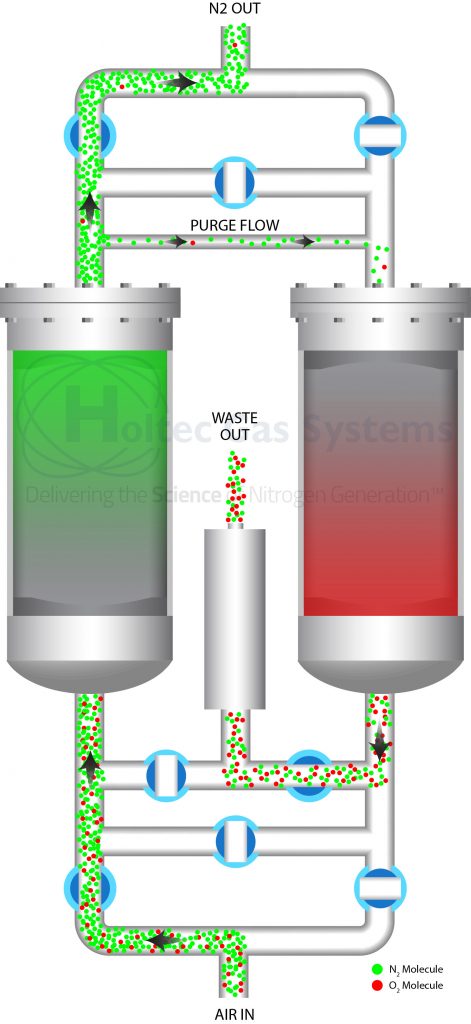

How Does a PSA Work? (see drawing to right)

A: See below and graphic at right for basic operation steps

Step 1: Pressurize adsorber “A” and then produce nitrogen until the separation media becomes saturated. During this time, adsorber “B” is depressurized and enriched oxygen gas is released to atmosphere as waste.

Step 2: Pressurize adsorber “B” and then produce nitrogen until separation media becomes saturated. During this time, adsorber “A” is depressurized and enriched oxygen gas is released to atmosphere as waste.

Step 3: The cycle repeats about every two minutes, beginning with Step 1, for as long as nitrogen demand continues, as determined by pressure transducer in nitrogen receiver.

What purity do I need?

A: Most companies choose a purity between 99%-99.9% for food and beverage applications. Holtec will be happy to help with the logistics of setting up your own evaluation.

How much nitrogen do I need?

A: To get a rough idea, it is possible to review bulk nitrogen purchase over a several month period. We are also happy to provide flow meters and engineering expertise in order to determine your instantaneous demand and evaluate usage patterns.

Can I keep liquid nitrogen as a backup?

A: Absolutely! However, you can send back your large rented liquid storage tank and purchase a much smaller storage tank which will drastically reduce the amount of liquid nitrogen lost to evaporation.

Is ambient air temperature important?

A: Yes. Temperature affects capacity and air consumption and nitrogen generator manufacturers typically will quote performance only at 70 °F. Holtec will always ensure that your actual conditions are taken into consideration.