Choose a different country or region to see the content specific to your location

Select Your Country/Region

Current Region:

Global (EN)

Global (EN)

How can we help you?

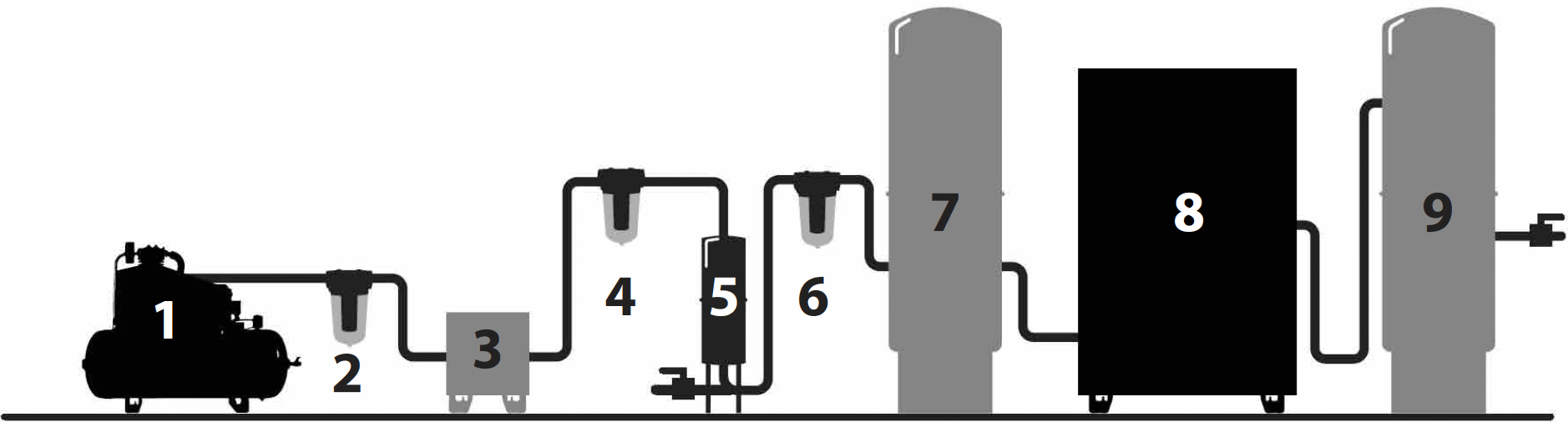

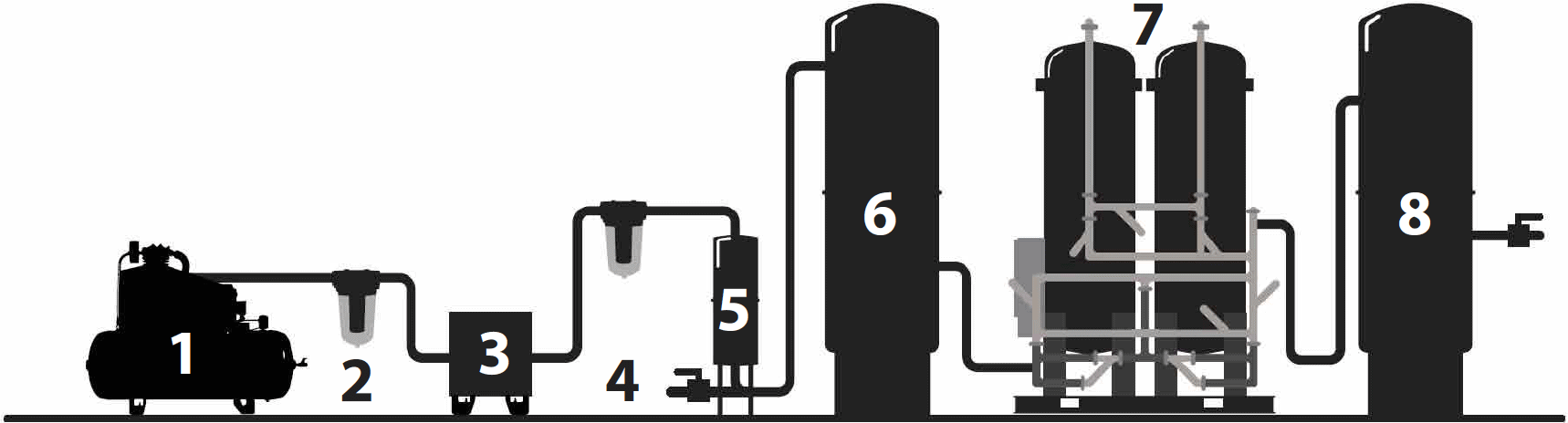

Holtec Gas Systems manufactures nitrogen generators based on both Pressure-Swing Adsorption and Membrane separation technologies. But which technology is right for you? While cost is a significant driver of this decision, there are many other factors which you should consider before choosing the best technology for your application.

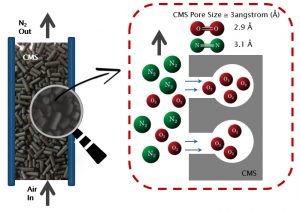

PSA technology works on the concept of adsorption – the process by which molecules temporarily adhere to the surface of materials they are in contact with. A PSA nitrogen generator consist of two or more adsorbers filled with separation material called carbon-molecular sieve (CMS). CMS is produced specifically to have pore sizes that correspond to the relatively small size of an oxygen molecule (compared to the relatiely larger nitrogen molecule.

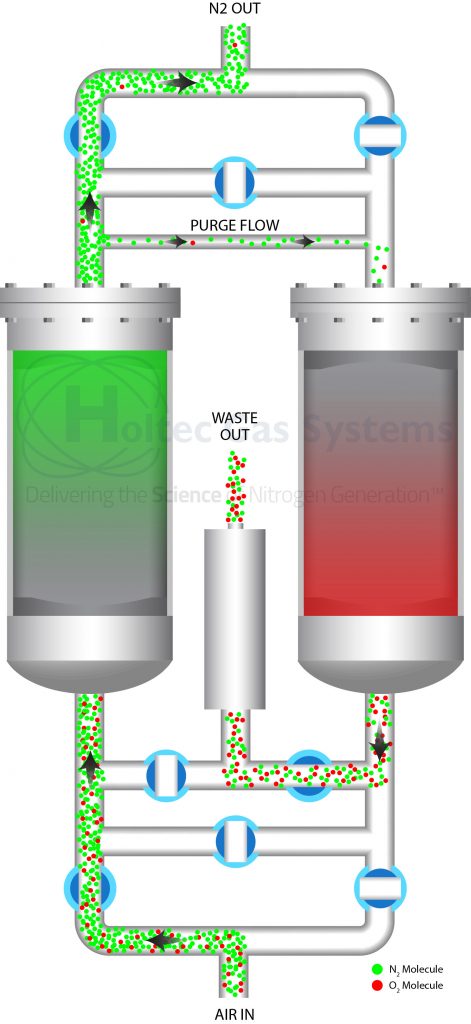

In a PSA nitrogen generator, cormpressed air is drawn from the atmosphere and directed into one adsorber. Under pressure, oxygen in the compressed air gets “stuck” in the pores of the CMS, allowing the remaining constituents (mostly nitrogen) to pass through the system unhindered.

Sounds simple, doesn’t it? There is only one problem. Eventually, oxygen molecules separation will no longer occur. This is called saturation, when oxygen molecules completely cover the surface of the CMS and there is no room for more to be adsorbed.

Fortunately, the adsorption process is reversed by depressurizing the adsorber. This is why PSA technology uses two or more adsorbers. At ambient pressure, oxygen is released from the surface of the CMS and is returned to the atmosphere as waste gas, thus regenerating the adsorber for use in the next cycle. While the first adsorber is regenerating, the second adsorber is actively producing nitrogen. At the end of the cycle, the first adsorber is once again ready to produce nitrogen and the second adsorber regenerates – and so on.

However, each time an adsorber cycles back on-line, there is a brief period during pressurization that no nitrogen is being produced. This is one reason why every PSA nitrogen generator requires a process nitrogen receiver tank.

Additionally, compressed air usage during the pressurization step is greater than the average flow. In order to ensure there is always enough clean, dry, oil-free compressed air to supply the system, a process air receiver is also usually needed.

Purification

1. Pressurized air in

2. Absorption of oxygen

3. High purity nitrogen out

Regeneration

4. Equalization of pressure (not depicted)

5. Regenerating bed depressurizes completely, allowing oxygen enriched gas to desorb

6. Waste gas exits through silencer

Through rigorous research and testing, Holtec has designed a proprietary simulation program in order to ensure that all filters, tanks, valves, and line sizes are properly sized for optimal operation, guaranteeing the least amount of customer problems. Maintenance is typically limited to standard compressor and dryer PM and regularly changing filters and activated carbon, which facilities utilizing compressed air are already familiar with.

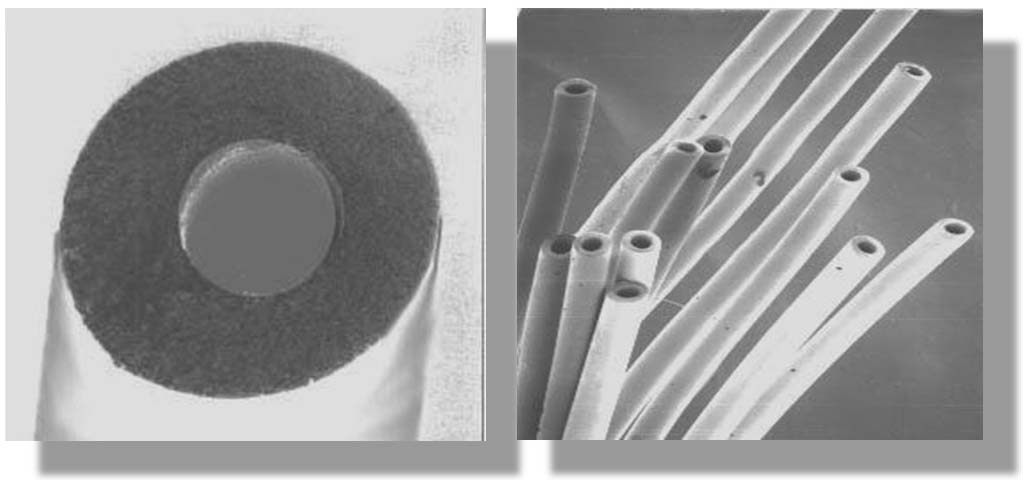

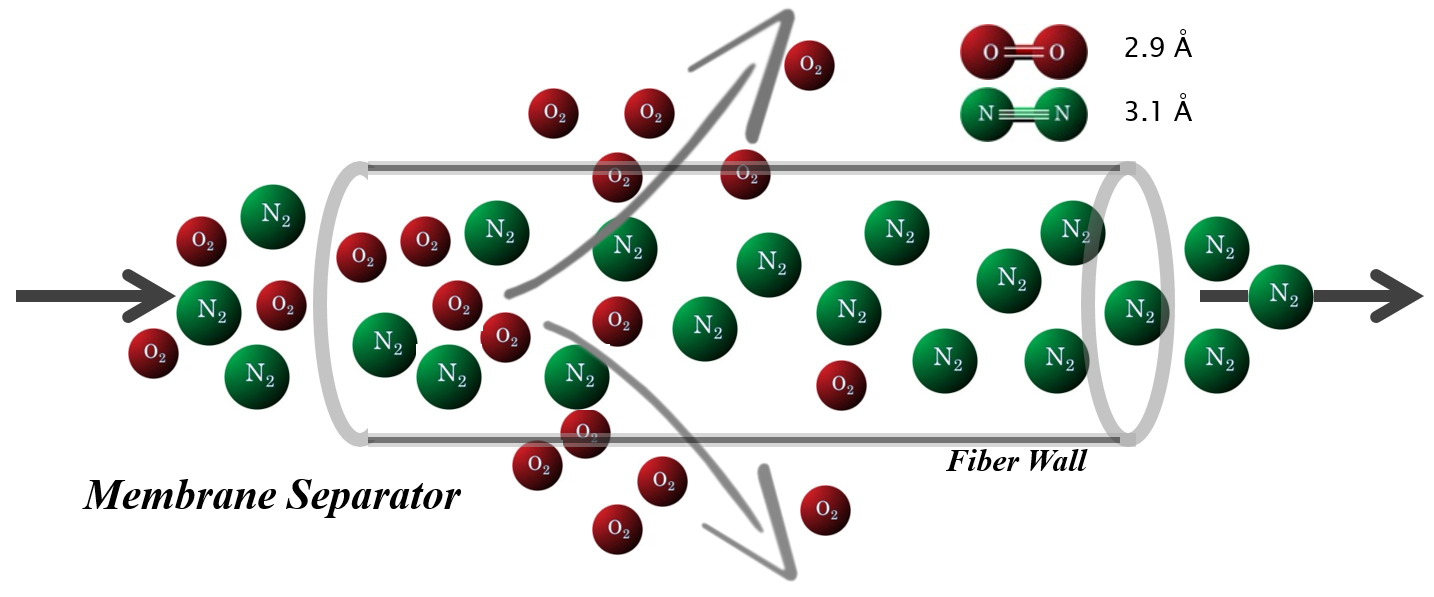

Membrane nitrogen generators separate nitrogen from atmosphere by passing compressed air through a permeable membrane. The process relies on the principle of selective gas permeation. Each gas has a different permeation rate, so as the compressed feed air stream passes across the membrane, gases with faster permeation rates like 02 and CO2 are released back into the atmosphere as waste gas (along with some N2)

The product nitrogen, now stripped of most of the oxygen and carbon dioxide, passes out the other end of the separator at a slightly lower pressure for collection or directly into your application. Unlike a PSA system, a nitrogen receiver tank is not necessarily needed.